Waya yemhangura ine enamel 0.05mm 2UEW/3UEW155/180 yekupisa coil

Musimboti wekushanda kwemota ignition coil ndeyekushandura voltage yakaderera yeDC kuita voltage yakakwira yeDC kuburikidza ne inversion uye dual voltage rectification iyo inopfuura nepakati pe primary ye ignition coil nguva nenguva. Voltage yakakwira inokonzerwa musecondary ye ignition coil (Kazhinji inenge 20KV) uye inobva yaita kuti spark plug ye ignition coil ibudise kuti ibatidzwe. Zvakaoma kudzora zvimwe zvinhu zvewaya yakajairika ye enamel yemota ignition coils sezvo waya yakatyoka inowanzoitika panguva yekushanda. Tichifunga nezvezvinodiwa zvakakosha zve ignition coils, kambani yedu inogadzira waya yakasarudzika ye enamel yemota ignition coils ine chitarisiko chakanaka, kugona kusveta zvakanaka, kuramba kunyorova zvakanyanya uye kugadzikana panguva yekugadzira. Tinoshandisa waya yemhangura yakadhonzwa iyo inotanga yakafukidzwa ne base coat soldering patembiricha yakaderera. Zvadaro waya yacho inoputirwa zvakare ne softening-resistant enamel. Zvikamu zvewaya iyi ipolyurethane ine high tembiricha.

Chimwe chezvinhu zvinoitwa newaya ine enamel (G2 H0.03-0.10) yekubatanidza mota ne coil yekupisa moto ndechekuti dhayamita yayo yakatetepa zvikuru. Yakanyanya kutetepa inongova chikamu chimwe muzvitatu chebvudzi remunhu. Uyezve, sezvo iri waya ine polyurethane enamel yakakora ye thermal class 180C, inoda zvakawanda pakugadzira. Kambani yedu ine ruzivo rwakakura uye tekinoroji yakakura mukugadzira waya ine enamel yekupisa mota ne coil. Maitiro ekugadzira akagadzikana.

1. Kuvandudzwa kwekudzivirira kupfava kuitira kuti isatyoke panguva yekupfava kana yapwanyika pa 260℃ * 2min.

2. Kushanda zvakanaka kwekusonesa, nzvimbo yekusonesa yakatsetseka uye yakachena isina slag yekusonesa pasi pemamiriro e390℃ * 2S.

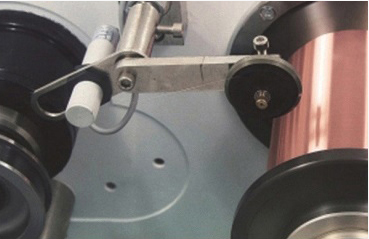

Mwero wekutyoka kwewaya mukugadzirwa kwayo unoderedzwa kubva panenge papfuura 20% kusvika pasi pe1%, kuitira kuti pamusoro payo pave panyoro uye kufambisa kwemhepo kugadzikane.

1. Tinoshandisa chinhu chinoputira simbi chinosanganisira: enamel ine simba rekuputira simbi rinodziya rinoshandiswa se base coat, uye enamel ine simba rekupfavisa simbi rinoshandiswa se topcoat kugadzira waya ine simba rekupfavisa simbi ine simba rekupfavisa simbi uye simba rekupfavisa simbi.

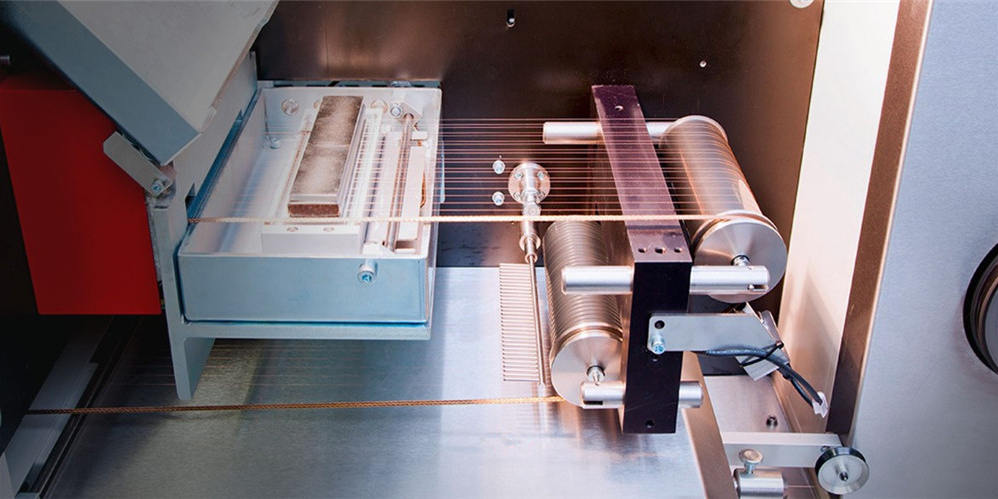

2. Kuvandudza tekinoroji yekugadzira waya ine enamel: kuchinja kwehuwandu hwemafuta ekudhonza panguva yekudhonza. Seti yemould yekugadzirisa kugadzirwa inobatsira kuti waya yemhangura itsvedzerere. Kuiswa kwemudziyo wekugadzirisa viscosity otomatiki uye mudziyo wekutonga tension otomatiki panguva yekudhonza enamel kunoderedza mwero wekutyoka kwewaya.

| Dhayamita | Kushivirira | Waya yemhangura ine enamel (dhayamita yese) | |||||

| (mm) | (mm) | Giredhi 1 | Giredhi 2 | Giredhi 3 | |||

| Minimum.(mm) | Kureba (mm) | Minimum.(mm) | Kureba (mm) | Minimum.(mm) | Kureba (mm) | ||

| 0.030 | * | 0.033 | 0.037 | 0.038 | 0.041 | 0.042 | 0.044 |

| 0.032 | * | 0.035 | 0.039 | 0.04 | 0.043 | 0.044 | 0.047 |

| 0.034 | * | 0.037 | 0.041 | 0.042 | 0.046 | 0.047 | 0.05 |

| 0.036 | * | 0.04 | 0.044 | 0.045 | 0.049 | 0.05 | 0.053 |

| 0.038 | * | 0.042 | 0.046 | 0.047 | 0.051 | 0.052 | 0.055 |

| 0.040 | * | 0.044 | 0.049 | 0.05 | 0.054 | 0.055 | 0.058 |

| 0.043 | * | 0.047 | 0.052 | 0.053 | 0.058 | 0.059 | 0.063 |

| 0.045 | * | 0.05 | 0.055 | 0.056 | 0.061 | 0.062 | 0.066 |

| 0.048 | * | 0.053 | 0.059 | 0.06 | 0.064 | 0.065 | 0.069 |

| 0.050 | * | 0.055 | 0.06 | 0.061 | 0.066 | 0.067 | 0.072 |

| 0.053 | * | 0.058 | 0.064 | 0.065 | 0.07 | 0.071 | 0.076 |

| 0.056 | * | 0.062 | 0.067 | 0.068 | 0.074 | 0.075 | 0.079 |

| 0.060 | * | 0.066 | 0.072 | 0.073 | 0.079 | 0.08 | 0.085 |

| 0.063 | * | 0.069 | 0.076 | 0.077 | 0.083 | 0.084 | 0.088 |

| 0.067 | * | 0.074 | 0.08 | 0.081 | 0.088 | 0.089 | 0.091 |

| 0.070 | * | 0.077 | 0.083 | 0.084 | 0.09 | 0.091 | 0.096 |

| 0.071 | ±0.003 | 0.078 | 0.084 | 0.085 | 0.091 | 0.092 | 0.096 |

| 0.075 | ±0.003 | 0.082 | 0.089 | 0.09 | 0.095 | 0.096 | 0.102 |

| 0.080 | ±0.003 | 0.087 | 0.094 | 0.095 | 0.101 | 0.102 | 0.108 |

| 0.085 | ±0.003 | 0.093 | 0.1 | 0.101 | 0.107 | 0.108 | 0.114 |

| 0.090 | ±0.003 | 0.098 | 0.105 | 0.106 | 0.113 | 0.114 | 0.12 |

| 0.095 | ±0.003 | 0.103 | 0.111 | 0.112 | 0.119 | 0.12 | 0.126 |

| 0.100 | ±0.003 | 0.108 | 0.117 | 0.118 | 0.125 | 0.126 | 0.132 |

| 0.106 | ±0.003 | 0.115 | 0.123 | 0.124 | 0.132 | 0.133 | 0.14 |

| 0.110 | ±0.003 | 0.119 | 0.128 | 0.129 | 0.137 | 0.138 | 0.145 |

| 0.112 | ±0.003 | 0.121 | 0.13 | 0.131 | 0.139 | 0.14 | 0.147 |

| 0.118 | ±0.003 | 0.128 | 0.136 | 0.137 | 0.145 | 0.146 | 0.154 |

| 0.120 | ±0.003 | 0.13 | 0.138 | 0.139 | 0.148 | 0.149 | 0.157 |

| 0.125 | ±0.003 | 0.135 | 0.144 | 0.145 | 0.154 | 0.155 | 0.163 |

| 0.130 | ±0.003 | 0.141 | 0.15 | 0.151 | 0.16 | 0.161 | 0.169 |

| 0.132 | ±0.003 | 0.143 | 0.152 | 0.153 | 0.162 | 0.163 | 0.171 |

| 0.140 | ±0.003 | 0.151 | 0.16 | 0.161 | 0.171 | 0.172 | 0.181 |

| 0.150 | ±0.003 | 0.162 | 0.171 | 0.172 | 0.182 | 0.183 | 0.193 |

| 0.160 | ±0.003 | 0.172 | 0.182 | 0.183 | 0.194 | 0.195 | 0.205 |

| 0.170 | ±0.003 | 0.183 | 0.194 | 0.195 | 0.205 | 0.206 | 0.217 |

| 0.180 | ±0.003 | 0.193 | 0.204 | 0.205 | 0.217 | 0.218 | 0.229 |

| 0.190 | ±0.003 | 0.204 | 0.216 | 0.217 | 0.228 | 0.229 | 0.24 |

| 0.200 | ±0.003 | 0.214 | 0.226 | 0.227 | 0.239 | 0.24 | 0.252 |

| Dhayamita | Kushivirira | Kuramba pa20 °C | ||

| mm | mm | Zita (ohm/m) | Min(ohm/m) | Max(ohm/m) |

| 0.030 | * | 24.18 | 21.76 | 26.6 |

| 0.032 | * | 21.25 | 19.13 | 23.38 |

| 0.034 | * | 18.83 | 17.13 | 20.52 |

| 0.036 | * | 16.79 | 15.28 | 18.31 |

| 0.038 | * | 15.07 | 13.72 | 16.43 |

| 0.040 | * | 13.6 | 12.38 | 14.83 |

| 0.043 | * | 11.77 | 10.71 | 12.83 |

| 0.045 | * | 10.75 | 9.781 | 11.72 |

| 0.048 | * | 9.447 | 8.596 | 10.3 |

| 0.050 | * | 8.706 | 7.922 | 9.489 |

| 0.053 | * | 7.748 | 7.051 | 8.446 |

| 0.056 | * | 6.94 | 6.316 | 7.565 |

| 0.060 | * | 6.046 | 5.502 | 6.59 |

| 0.063 | * | 5.484 | 4.99 | 5.977 |

| 0.067 | * | 4.848 | 4.412 | 5.285 |

| 0.070 | * | 4.442 | 4.042 | 4.842 |

| 0.071 | ±0.003 | 4.318 | 3.929 | 4.706 |

| 0.075 | ±0.003 | 3.869 | 3.547 | 4.235 |

| 0.080 | ±0.003 | 3.401 | 3.133 | 3.703 |

| 0.085 | ±0.003 | 3.012 | 2.787 | 3.265 |

| 0.090 | ±0.003 | 2.687 | 2.495 | 2.9 |

| 0.095 | ±0.003 | 2.412 | 2.247 | 2.594 |

| 0.100 | ±0.003 | 2.176 | 2.034 | 2.333 |

| 0.106 | ±0.003 | 1.937 | 1.816 | 2.069 |

| 0.110 | ±0.003 | 1.799 | 1.69 | 1.917 |

| 0.112 | ±0.003 | 1.735 | 1.632 | 1.848 |

| 0.118 | ±0.003 | 1.563 | 1.474 | 1.66 |

| 0.120 | ±0.003 | 1.511 | 1.426 | 1.604 |

| 0.125 | ±0.003 | 1.393 | 1.317 | 1.475 |

| 0.130 | ±0.003 | 1.288 | 1.22 | 1.361 |

| 0.132 | ±0.003 | 1.249 | 1.184 | 1.319 |

| 0.140 | ±0.003 | 1.11 | 1.055 | 1.17 |

| 0.150 | ±0.003 | 0.9673 | 0.9219 | 1.0159 |

| 0.160 | ±0.003 | 0.8502 | 0.8122 | 0.8906 |

| 0.170 | ±0.003 | 0.7531 | 0.7211 | 0.7871 |

| 0.180 | ±0.003 | 0.6718 | 0.6444 | 0.7007 |

| 0.190 | ±0.003 | 0.6029 | 0.5794 | 0.6278 |

| 0.200 | ±0.003 | 0.5441 | 0.5237 | 0.5657 |

Transformer

Mota

Koiri yekubatidza

Koiri Yezwi

Zvemagetsi

Kutumira

Kutungamirirwa nevatengi, Kugadzira zvinhu zvitsva kunounza kukosha kwakawanda

RUIYUAN inopa mhinduro, izvo zvinoda kuti tive nyanzvi pawaya, zvinhu zvinodzivirira kupisa uye mashandisirwo azvo.

Ruiyuan ine nhaka yekuvandudza zvinhu zvitsva, pamwe nekufambira mberi mukugadzira waya dzemhangura dzakagadzirwa ne enamel, kambani yedu yakakura kuburikidza nekuzvipira kusingazununguki kukuvimbika, sevhisi uye kupindura kune vatengi vedu.

Tinotarisira kuramba tichikura zvichibva pamhando yepamusoro, hunyanzvi hutsva uye sevhisi.

Mazuva 7-10 Avhareji yenguva yekutumira.

90% vatengi vekuEurope neNorth America. Vakadai sePTR, ELSIT, STS nezvimwewo.

95% Mutengo wekutengazve

99.3% Kugutsikana. Mutengesi weKirasi A akasimbiswa nemutengi wekuGermany.