Waya yemhangura yeHCCA 2KS-AH 0.04mm inozvibatanidza yoga

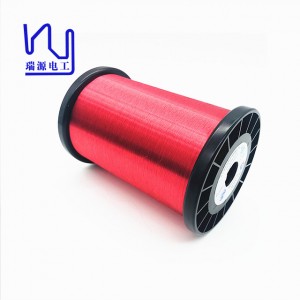

Waya inonamira yesimbi yakaputirwa nearuminiyamu inoenderana nezvinodiwa zvekuvandudza kushandiswa kwewaya pasina kukanganisa kunaka kweruzha (high-frequency voice coil). Bond coat yewaya inogona kushandiswa nenzira mbiri dzemhepo inopisa uye solvent. Waya iyi inofarirwa nevatengi vazhinji nekuda kwemaitiro ayo ekuigadzira uye mutengo wayo wakaderera. Dhayamita yewaya iyi yakatetepa.

Mushure mekuongorora dhipatimendi reRUIYUAN R&D kwenguva yakareba, takaona kuti zvinodiwa zvekuchengetedza zvakatipoteredza uye kuchengetedza simba zviri kuwedzera. Saka zviri nani kugadzira rudzi rutsva rwewaya inonamira pachayo inogona kutsungirira kupisa kwakanyanya uye inogona kusungwa kana tembiricha yakaderera.

Waya yedu itsva yakagadzirwa nemhepo inopisa ine enamel yemhangura ine enamel yekupisa yakaderera uye inoshandiswa pakupisa kwakanyanya uye waya yekubatanidza solvent inogona kupfupisa nguva yekubatanidza yakagadzirirwa kugutsa zvinodiwa zvekuchengetedza simba. Mhedzisiro yekuyedza inoratidza kuti waya yedu yemagineti yekubatanidza solvent yakagadzirwa nefomula itsva ine mashandiro akanaka uye hunhu hwakanaka pakupisa kwe180℃×10 ~ 15min apo waya itsva yemhangura ine enamel yemhepo inopisa inonamira pachayo isingakuvadzi nharaunda zvakare.

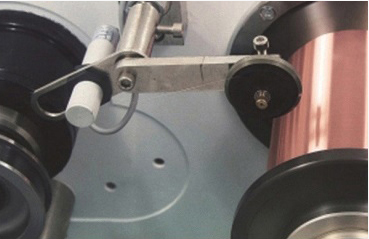

Kugadzirwa kwe coil yezwi inoda kutenderera kwekukurumidza, kwekudengenyeka kwenyika uye kwesimba rinodzivisa kudhonzwa kunoisa zvinodiwa zvitsva kune vanofambisa waya yemagneti inonamira yega. Simba rekudhonzwa kwe coil yemhangura ine alloy yakakodzera rinogona kuwedzerwa neinenge 20 ~ 30% kana tichienzanisa ne conductor wemhangura yakajairika, kunyanya kune waya inonamira yega. Waya dzemagneti dzinonamira yega dzine alloy conductor uye high tension resistance dziri kufarirwa mukugadzirwa kwe high-end voice coils. Muchidimbu, kugadzira bond coat imwe chete uye bonding magnet wire ine high-frequency audio transmission, huremu hwakareruka, simba rakawanda uye hunyanzvi hwe high-end voice coils kwave kutungamira kwaRuiyuan mune ramangwana.

Technical Parameter Tafura Ye Enameled Stranded Wire

| Chinhu Chekuyedza | Chikamu | Kukosha Kwakajairika | Kukosha Kwechokwadi | ||

| Zviyero zvemutyairi | mm | 0.040±0.001 | 0.040 | 0.040 | 0.040 |

| (Zviyero zveBasecoat) Zviyero zvese | mm | 0.053 yepamusoro | 0.0524 | 0.0524 | 0.0524 |

| Kuputira Firimu Ukobvu | mm | Minimum0.002 | 0.003 | 0.003 | 0.003 |

| Kubatanidza Firimu Ukobvu | mm | Minimum0.002 | 0.003 | 0.003 | 0.003 |

| (50V/30m) Kuenderera mberi kwekuvhara | zvidimbu. | Makirogiramu makumi matanhatu (60) | Max.0 | ||

| Kutevedzera | Hapana kutsemuka | Kugona | |||

| Kuparara kweVoltage | V | Minimum.475 | Min.1302 | ||

| Kuramba Kunyoroveswa (Cheka Nepakati) | ℃ | Ramba uchipfuura kaviri | 200℃/Zvakanaka | ||

| (390℃±5℃) Kuedzwa kweSolder | s | 2 Yakanyanya | 1.5 Yakanyanya | ||

| Simba rekubatana | g | Minimum.5 | 11 | ||

| (20℃) Kuramba Kwemagetsi | Ω/m | 21.22-22.08 | 21.67 | 21.67 | 21.67 |

| Kureba | % | Minimum.4 | 8 | 8 | 8 |

| Chitarisiko chepamusoro | Ruvara rwakatsetseka | Kugona | |||

Transformer

Mota

Koiri yekubatidza

Koiri Yezwi

Zvemagetsi

Kutumira

Kutungamirirwa nevatengi, Kugadzira zvinhu zvitsva kunounza kukosha kwakawanda

RUIYUAN inopa mhinduro, izvo zvinoda kuti tive nyanzvi pawaya, zvinhu zvinodzivirira kupisa uye mashandisirwo azvo.

Ruiyuan ine nhaka yekuvandudza zvinhu zvitsva, pamwe nekufambira mberi mukugadzira waya dzemhangura dzakagadzirwa ne enamel, kambani yedu yakakura kuburikidza nekuzvipira kusingazununguki kukuvimbika, sevhisi uye kupindura kune vatengi vedu.

Tinotarisira kuramba tichikura zvichibva pamhando yepamusoro, hunyanzvi hutsva uye sevhisi.

Mazuva 7-10 Avhareji yenguva yekutumira.

90% vatengi vekuEurope neNorth America. Vakadai sePTR, ELSIT, STS nezvimwewo.

95% Mutengo wekutengazve

99.3% Kugutsikana. Mutengesi weKirasi A akasimbiswa nemutengi wekuGermany.